Aquascot launches two new Scottish salmon products at Waitrose

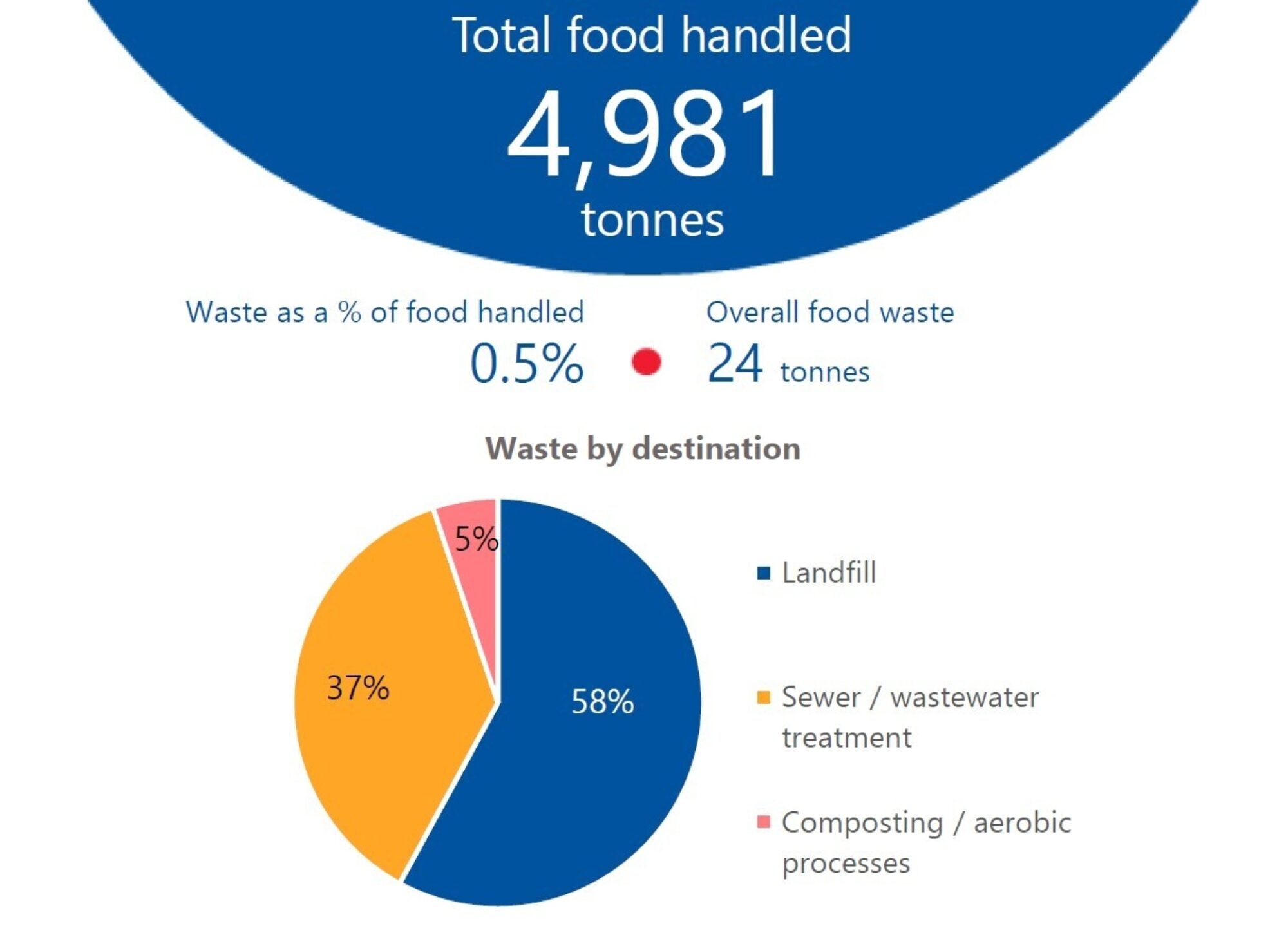

Each year we set a food waste reduction target, as part of our commitment to reduce our food waste by 50% by 2030. In our first full year of reporting, we have achieved a significant reduction in our food waste of almost 50%, and our target for 2020/2021 is to achieve a further 10% reduction.

Actions in the past year have led to significant reduction (65%) in material going to landfill and our overall food waste inventory has reduced by 49.8%. This has been mainly supported by improving our internal yields and material usage, as well as establishing stronger links with other elements of the overall supply chain.

We are now segregating our food waste to allow for dedicated collection to avoid landfill, and this will have a positive effect during our next 12-month reporting period. This separate food waste collection for canteen waste and ingredient wastage is being composted.

The relocation of our Primary processing, and installation of a new trade effluent system took place late in this reporting period (May 2020). The coming year will focus on maximising the benefit that this investment can realise, in further improving yields and reducing our food waste to sewer/wastewater treatment.

There has been a significant increase in the volume of by-product being sent for animal feed and fish oil processing. This has been offset by a reduction in by-product material being made available for human consumption. While this has had a positive impact in reducing our food waste volume, we will continue to explore options to increase the redistribution for human consumption during 2020/21.

Fish Supply Partners Aquaculture Protocol and Raw Material Quality Acceptance checks are in place providing information back to our fish suppliers on the quality of the fish arriving and being processed. Genetics, disease, veterinary treatments and harvesting practices can reduce carcass utilisation and increase food waste.

We have actively engaged with Waitrose on their Food Waste Reduction forum and will continue to engage positively in supporting Waitrose in their food waste reduction initiatives.

At the beginning of COVID-19 lockdown (March 2020) approximately 40kg of fish was donated to a local COVID-19 support group each week for approximately 8 weeks. This material would have been downgraded if it had not been used in this manner.

We have a new waste contractor that is able to provide more accurate data on waste streams which will help us to better understand our waste streams and areas of focus.

You can read the full WRAP report here: Aquascot TMA Case Study 16 09 20

Aquascot launches two new Scottish salmon products at Waitrose

Introducing Our New Summer Dish: Fresh Pesto Filled Scottish Salmon Fi...

Aquascot is excited to announce our involvement in the new 'Simply Bak...

Aquascot has appointed Fred Bowden as Chairman of the Aquascot Board, ...